Metalens Foundry

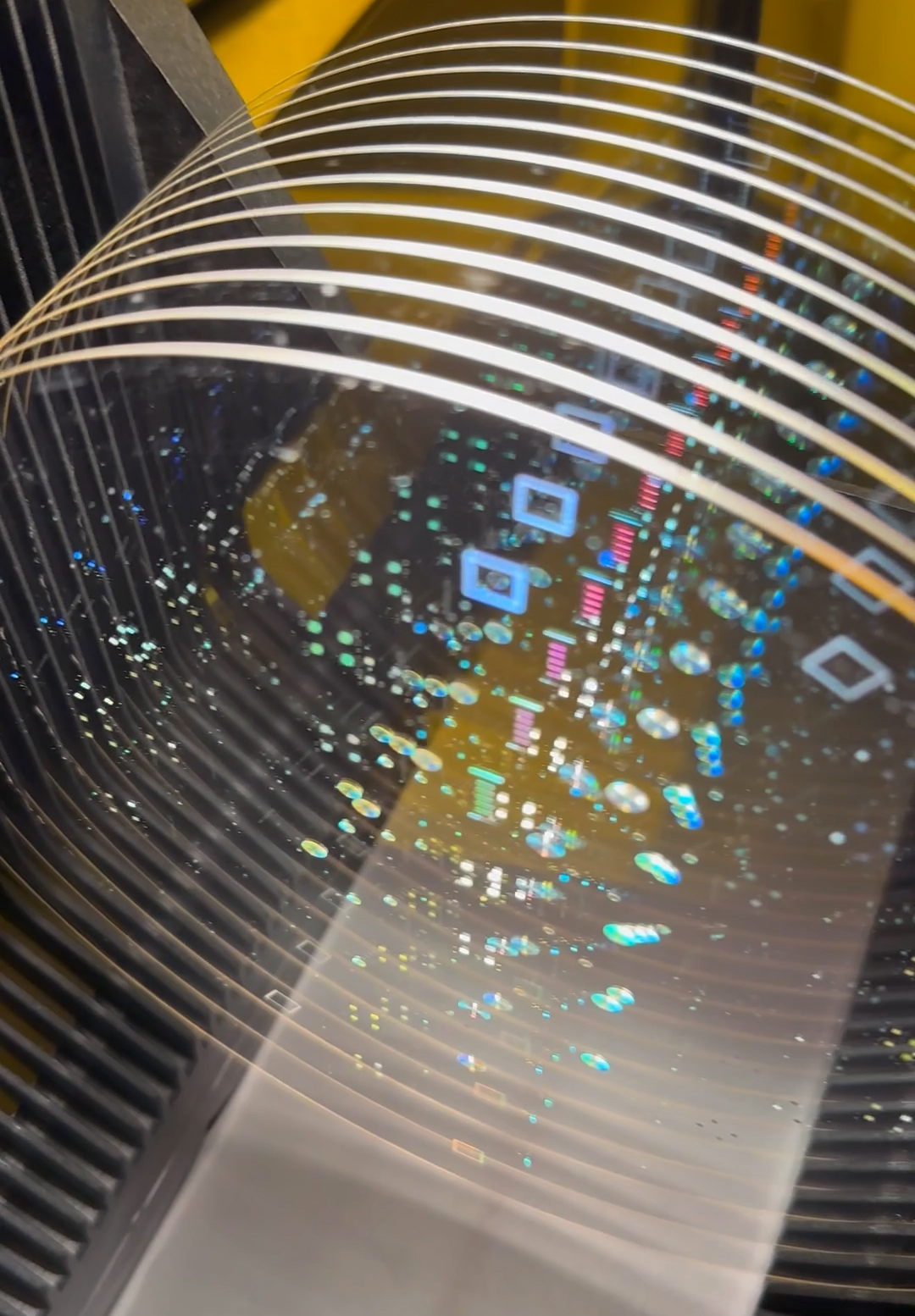

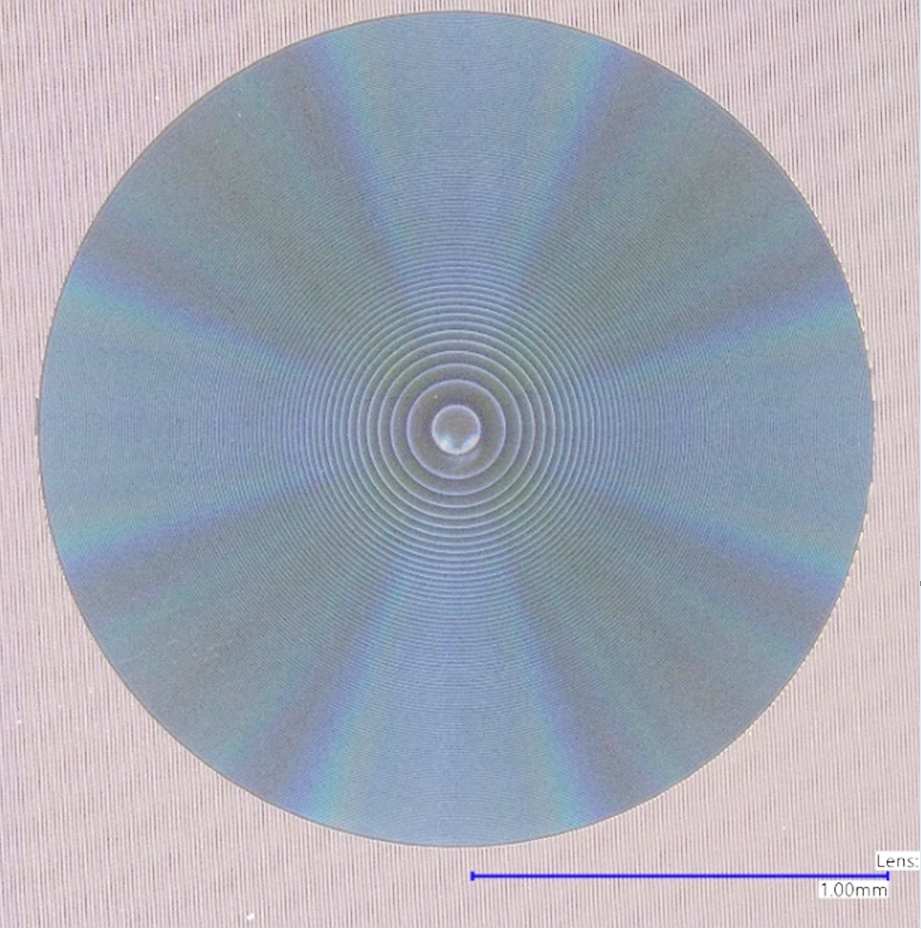

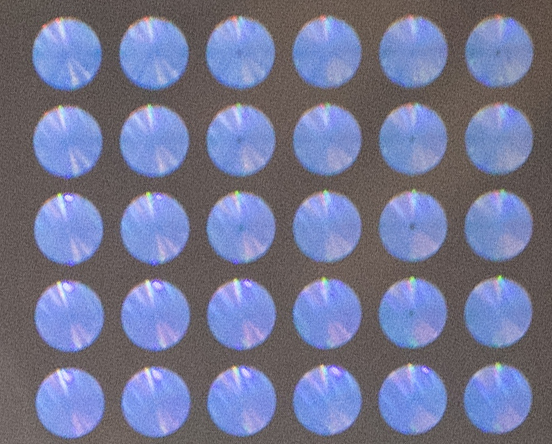

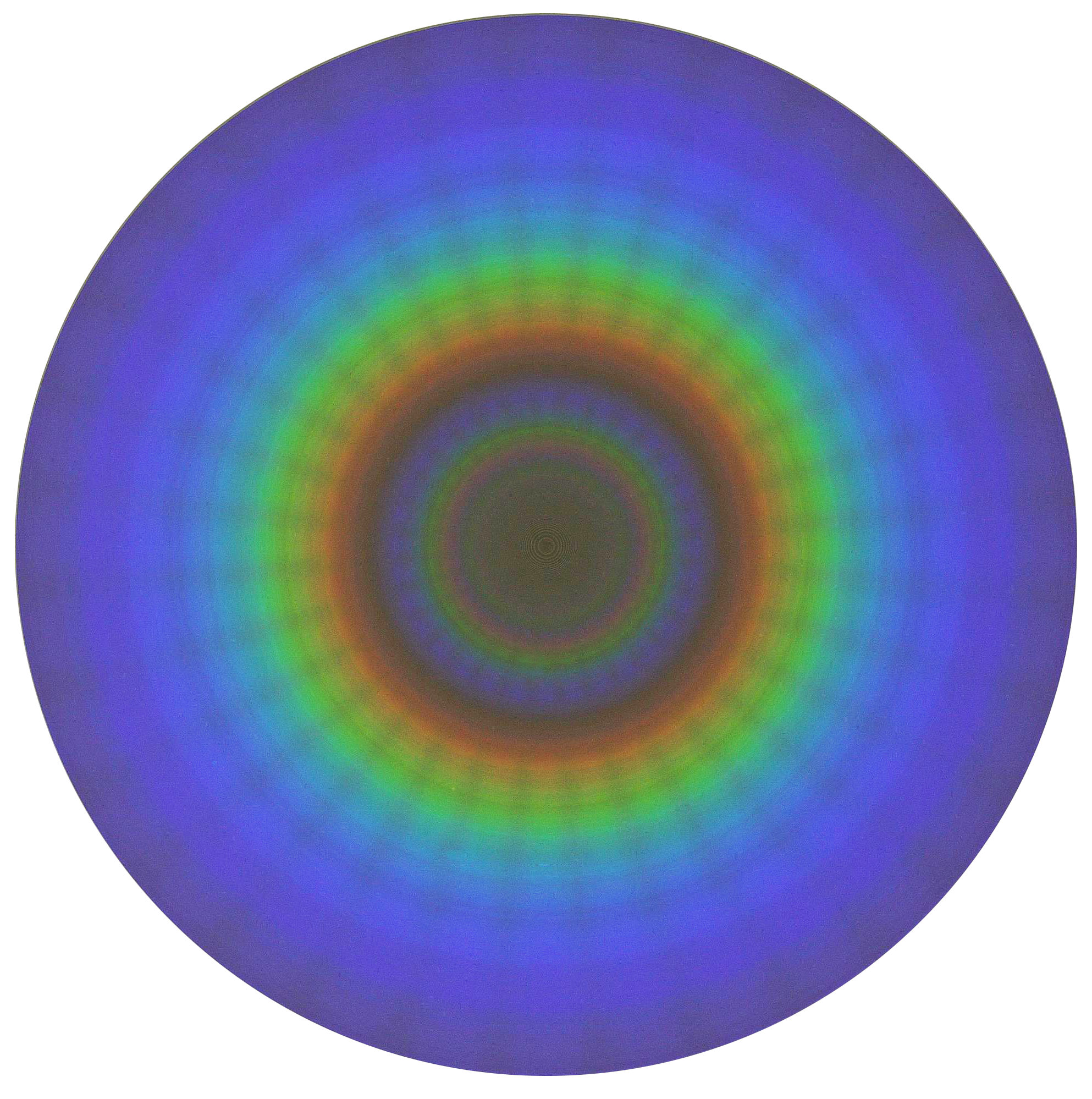

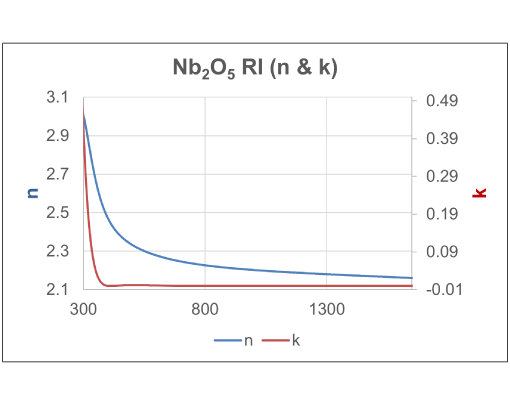

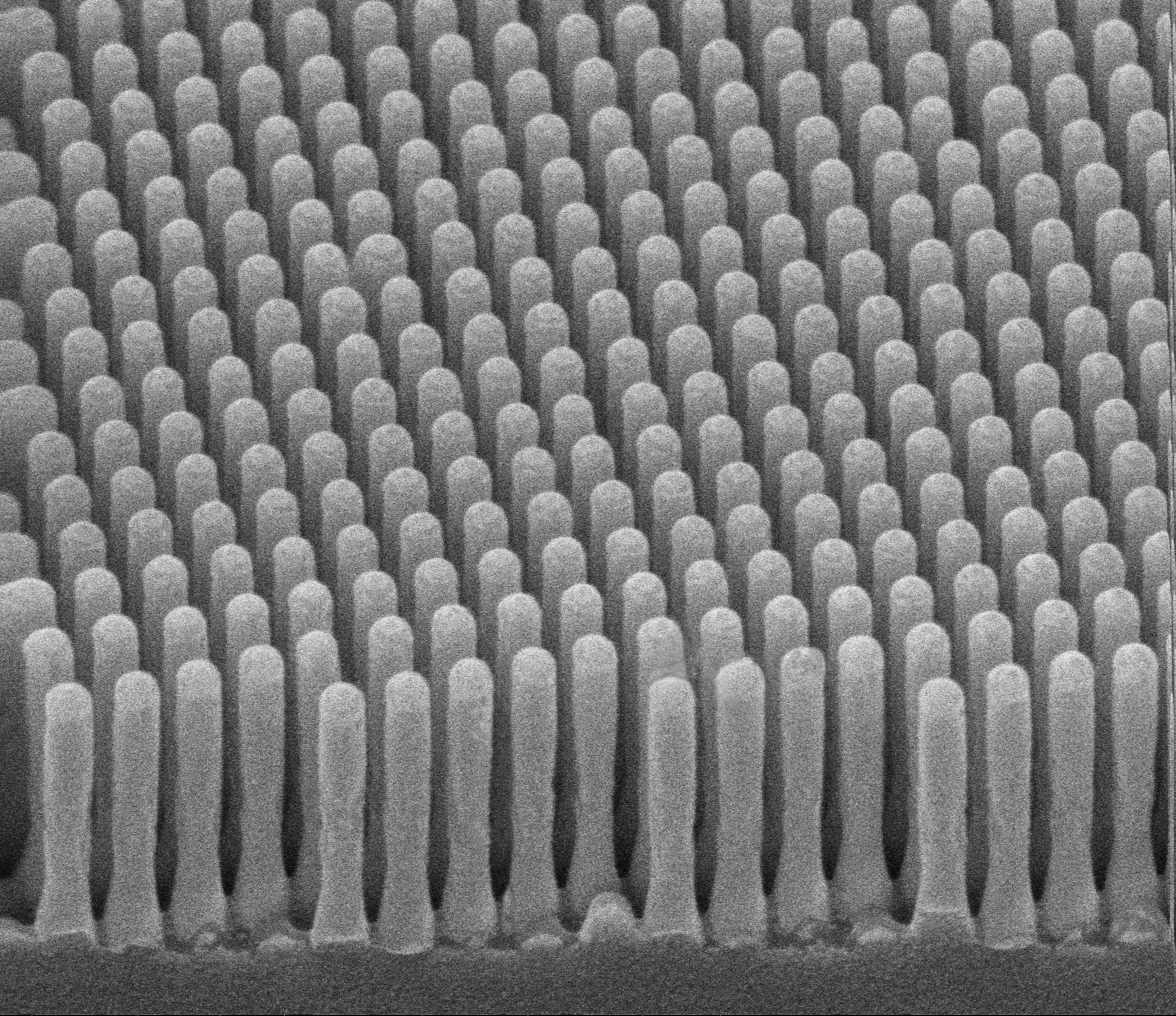

Moxtek has been manufacturing nanoscale structures for over 20 years. We have developed efficient methods to create e-beam masters combined with our existing NIL processing to provide a full solution approach to volume production. Moxtek can optimize the lens design to match customers applications. Moxtek offers design, fabrication, measurement, and packaging capabilities. Moxtek has production facilities in USA, Japan, and China.Manufacturing Metalenses for the visible range imparts demanding nanofabrication requirements. To manufacture metalenses and other metastructured devices in volume, Nanoimprint Lithography (NIL) becomes a key enabling technology. Moxtek has used NIL to successfully demonstrate scalability and the ability to reliably replicate metalenses with extremely tight tolerances, including variations in local spacing. By using the NIL relief structure to etch high refractive index, high aspect ratio niobium oxide nanostructures, Moxtek has produced a variety of visible metalenses with different focal lengths. Building on years of expertise, Moxtek has developed reliable methods to manufacture wafer-scale visible metalenses for various emerging applications.